"Grindintosecond" (Grindintosecond)

"Grindintosecond" (Grindintosecond)

03/28/2015 at 17:20 • Filed to: None

0

0

33

33

"Grindintosecond" (Grindintosecond)

"Grindintosecond" (Grindintosecond)

03/28/2015 at 17:20 • Filed to: None |  0 0

|  33 33 |

I'm looking at the overlooked. The mid-range power band. Quite a few of us look at max power at what RPM but where we drive is in the middle. When it comes to building maximum power, for the middle RPM, say 4,000, what enhances this the most? Hogging out the cylinder for maximum flow isn't the answer in this range is it? Big cams aren't either right? Since power is just a math formula from the actual figure of torque, then what's the key(s) to building big torque at a target RPM?

I'm looking purely at N/A here. If making enormous high rpm power is based on machine shop magic of flow and rpm maximums, then I would assume the opposite for the lower rpm goals. Cleaning up flow so it's not disturbed and using cams for the magical gains of targeting maximum internal pressure at that rpm to me, seems the answer, but is it?

How would you approach a customer who said, "Duuuude I want an awesome engine man...I want the most power you can get. At 4k rpm, and fat power all the way to it. Brah I got monies!"

E30Joe drives a Subaru

> Grindintosecond

E30Joe drives a Subaru

> Grindintosecond

03/28/2015 at 17:23 |

|

A turbo

E. Julius

> Grindintosecond

E. Julius

> Grindintosecond

03/28/2015 at 17:23 |

|

Curious about this one as well. I've studied engines a fair amount so I have some ideas, but I'm not sure if they're correct so I'm interested to see what someone more knowledgeable has to say.

BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

> Grindintosecond

BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

> Grindintosecond

03/28/2015 at 17:25 |

|

Increase the top end as well. That will bring up the middle part of the power band.

bob and john

> Grindintosecond

bob and john

> Grindintosecond

03/28/2015 at 17:27 |

|

you need the correct airflow and maybe bump up the compression a bit. But short of a turbo, there isnt really that much your can do.

Arch Duke Maxyenko, Shit Talk Extraordinaire

> Grindintosecond

Arch Duke Maxyenko, Shit Talk Extraordinaire

> Grindintosecond

03/28/2015 at 17:28 |

|

Because this is the only way that I can reply to the main post, I have to tag the picture.

But for your question I'm going with large displacement and a mild cam.

E. Julius

> Grindintosecond

E. Julius

> Grindintosecond

03/28/2015 at 17:29 |

|

FWIW my guess is that things like raising the compression ratio and making the fuel mixture richer would help, since these would increase power but aren't dependent on engine speed. Probably a bunch of other stuff too though.

CRider

> E30Joe drives a Subaru

CRider

> E30Joe drives a Subaru

03/28/2015 at 17:34 |

|

Supercharger would probably do a better job at the low end

jariten1781

> Grindintosecond

jariten1781

> Grindintosecond

03/28/2015 at 17:36 |

|

How would you approach a customer who said, "Duuuude I want an awesome engine man...I want the most power you can get. At 4k rpm, and fat power all the way to it. Brah I got monies!"

Build em a stroker.

Grindintosecond

> E30Joe drives a Subaru

Grindintosecond

> E30Joe drives a Subaru

03/28/2015 at 17:38 |

|

"....I'm looking purely at N/A here....."

You missed this middle part of the post there between the top and bottom. :)

Grindintosecond

> CRider

Grindintosecond

> CRider

03/28/2015 at 17:39 |

|

I posted about this being N/A....got missed by a few peeps.

CRider

> Grindintosecond

CRider

> Grindintosecond

03/28/2015 at 17:42 |

|

I didn't miss that. If you want low RPM power, a supercharger is the best way to go. Sans forced induction, there's no replacement for displacement.

nafsucof

> CRider

nafsucof

> CRider

03/28/2015 at 17:43 |

|

plus most superchargers make NA motors feel like more powerful NA.

nafsucof

> Grindintosecond

nafsucof

> Grindintosecond

03/28/2015 at 17:45 |

|

a good tune will help the mid range or power under the curve. My svts tune adjusted the manifold changeover to a lower rpm and made a bunch more midrange torque. Also, don't do an exhaust or off-road pipe if you want to maintain midrange as less restriction reduces said torque.

Grindintosecond

> bob and john

Grindintosecond

> bob and john

03/28/2015 at 17:45 |

|

I do notice in dyno charts and the like, that good high rpm power engines have torque peaks around 4k or just after. A cam that works for a big power engine might work out better but the airflow would have to be matched for only that rev range interested in instead of going for top power, otherwise mid power is sacrificed for that big gain up top due to unmatched flow? that's what's going on in my head.

cletus44 aka Clayton Seams

> Grindintosecond

cletus44 aka Clayton Seams

> Grindintosecond

03/28/2015 at 17:48 |

|

How do you add mid-range? Add cubes.

Grindintosecond

> nafsucof

Grindintosecond

> nafsucof

03/28/2015 at 17:50 |

|

Honestly this is a straight designed engine. No variable cam, tune to your hearts content. I'm trying to discover how someone would configure an engine for targeting torque at a specific place. Not through tunes or other ways after its already built. Basically, designing the engine for that purpose first instead of relying on aftermarket.

Grindintosecond

> cletus44 aka Clayton Seams

Grindintosecond

> cletus44 aka Clayton Seams

03/28/2015 at 17:56 |

|

Say you have the cubes but the mid-range is too low. You're N/A. How would you build that engine to solve the problem. What rod/stroke ratio would you use to obtain the right exhaust velocity for scavenging? What percentage of the bore would you make the intake valve for charge filling at that rpm? Optimizing the design first for X-rpm torque is the solution because stroking the engine and adding cubes will fix many things but the optimal design for target torque is out the window if the exhaust velocity is too high for the valve sizes, etc. Those are the things i'm trying to discover. a tune or boost isnt the answer like quite a few people are saying here.

nafsucof

> Grindintosecond

nafsucof

> Grindintosecond

03/28/2015 at 18:02 |

|

than an intake manifold with long intake runners will improve low/midrange torque. Headers with short tubes, with more than a single junction also to help provide back pressure. Those will make the top end feel more bottled up but will improve the low/midrange. Any cams you get will typically move the power and to the right(read higher rpm) as factory cams on non performance applications are tuned for the midrange anyways...

E30Joe drives a Subaru

> Grindintosecond

E30Joe drives a Subaru

> Grindintosecond

03/28/2015 at 18:03 |

|

I know you want NA but think of all the spools

Baeromez

> Grindintosecond

Baeromez

> Grindintosecond

03/28/2015 at 18:12 |

|

An engine with a relatively small bore and a long stroke would achieve this nicely. The shorter the stroke, the higher the rev potential because the piston doesn't need to travel as far. However, the motion of the stroke is what produces torque, so if you want a low revving, torque-y motor you build a stroker.

Baeromez

> Baeromez

Baeromez

> Baeromez

03/28/2015 at 18:20 |

|

Also, a longer, smaller diameter intake runner helps with low to mid torque. As do small diameter, long tube headers.

Opposite Locksmith

> Grindintosecond

Opposite Locksmith

> Grindintosecond

03/28/2015 at 19:44 |

|

boost has done me some good!

2.5 liter WRX owner

505 - morphine not found

> Grindintosecond

505 - morphine not found

> Grindintosecond

03/28/2015 at 20:02 |

|

I am not an engineer, nor have i tuned a motor myself / had one tuned for me. So take this with a pinch of salt, but if this hypothetical engine we are talking about has EFI, i would probably first look at the chip. I'm not talking about some plug-n-play stuff here, i'm talking about a pro hooking up your chip to a computer, and adjusting the values until you arrive at a nice, steadily rising power curve without much dipping or waves. Of course for best results you might want to adjust the cam to this end too, so that you can have more / less air where needed for the new curve, but I wouldn't touch much anything else.

Why? Because factories want their engines to work best in mid-range too, so if their engineers did a half-decent job, your motor should only need small adjustments.

Now if you want to raise torque in the mid range, i think that equals raising it overall, so then basically tune the engine whichever way you see fit, just tell the guy doing the programming that your aren't looking for the highest possible peak, but for a nice steady raising curve.

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> E30Joe drives a Subaru

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> E30Joe drives a Subaru

03/28/2015 at 20:03 |

|

As the owner of a FieSTa I agree. The BRZ has more horsepower (and less torque) but its especially evident in the midrange, the fact that 85% of that HP and TQ is on tap between 2000 and 4000 rpm is a big deal.

E30Joe drives a Subaru

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

E30Joe drives a Subaru

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

03/28/2015 at 20:13 |

|

Bottom line if you dont want to live near the redline you'll need a way to cram more air in to your engine at lower RPM, which is where FI becomes useful.

Making a torque monster NA motor with a lot of displacement is hard.

Drakkon- Most Glorious and Upright Person of Genius

> Grindintosecond

Drakkon- Most Glorious and Upright Person of Genius

> Grindintosecond

03/28/2015 at 21:46 |

|

Is this a theoretical engine? or a specific one? The answers may vary. In general.

More displacement.

Fewer large valves (instead of many small ones).

Longer intake runners

Smaller volume intake plenum

Direct injection

Very turbulent inside cylinder

If cross plane V8 or V6, you would want short exhaust tubes (does not need to be equal length) getting to a large exhaust pipe quickly.

If flat-plane V8 or I4, you want longer equal length headers for maximum pulse-scavenging.

Grindintosecond

> Drakkon- Most Glorious and Upright Person of Genius

Grindintosecond

> Drakkon- Most Glorious and Upright Person of Genius

03/28/2015 at 22:23 |

|

The engine in question is a two-valve head. How would a flat-4 VW work with the exhaust pipe configuration you spoke of? So large valves to let the intake runner velocity in, but minimal intake plenum so individual throttle bodies with long big velocity stacks? or a single throttle on the end of the "high rise" intake?

Drakkon- Most Glorious and Upright Person of Genius

> Grindintosecond

Drakkon- Most Glorious and Upright Person of Genius

> Grindintosecond

03/28/2015 at 23:31 |

|

That answers a lot.

Exhaust pulse tuning on a flat-4 will not work. It only works on engines with evenly timed exhaust events that share the same plumbing. On a VW flat4 our two banks are too far apart.

If you are using carbs or throttle-body injection, you won't really have a plenum per se so you can ignore that, too. You can only really use that concept with port or direct FI.

The large valves allow a large gulp of low speed air (mid range) and usually allow for a turbulent mixture which is what you want.

Here is the trick for intake runners. Each runner has a perfect RPM. Longer runners are better for low RPM, shorter runners are better for high RPM operation. You would choose longer, but any length will have a compromise. BMW tried an experimental movable intake length that could be perfectly tuned to every RPM. How 'bout that?

RallyWrench

> Drakkon- Most Glorious and Upright Person of Genius

RallyWrench

> Drakkon- Most Glorious and Upright Person of Genius

03/29/2015 at 01:10 |

|

My Lancia Flavia is a 1500cc flat 4, twin carbs on top & exhaust on bottom, and its exhaust runners scavenge one another. Whether it actually helps, I can't answer, but thought it was relevant to mention.

Old-Busted-Hotness

> Grindintosecond

Old-Busted-Hotness

> Grindintosecond

03/29/2015 at 07:13 |

|

If you're designing the engine from scratch, go with a smallish bore and a long stroke. Smallish ports and valves to keep port velocity high, and an "RV cam" with lots of lift but not a lot of duration or overlap (wider lobe-separation angle). Tri-Y headers if it's a V8 or inline 4/6 and a long intake runner.

Grindintosecond

> Drakkon- Most Glorious and Upright Person of Genius

Grindintosecond

> Drakkon- Most Glorious and Upright Person of Genius

03/29/2015 at 14:19 |

|

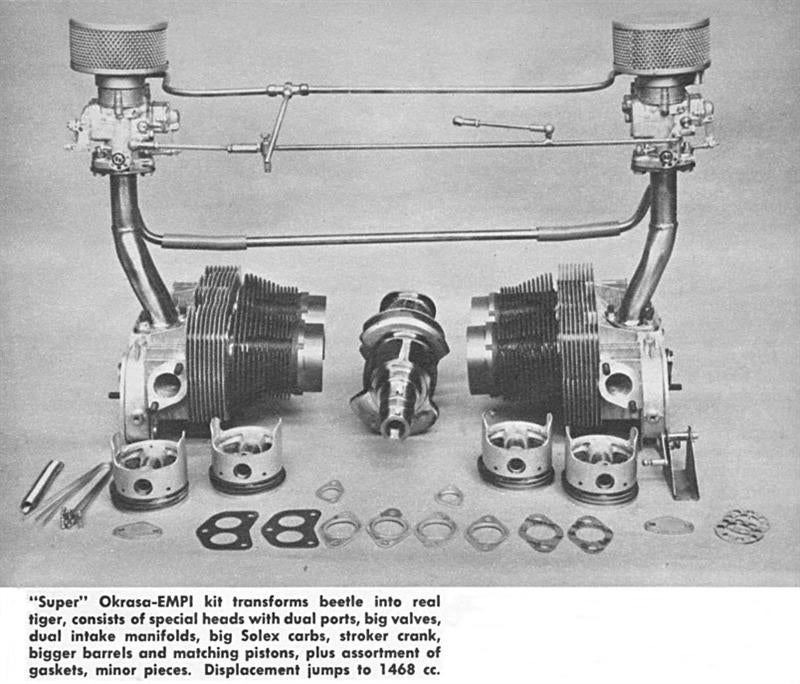

Here is the engine i'm throwing this optimization at. I would like some opinion from you on it. It fits a specific purpose because of it's weight and reliable power at that weight. (not my picture)

Believe it or not, a cut in half VW type-2 like this generates 45hp@3400rpm at a 1200cc displacement. Thats a 94mm x 86mm bore/stroke. Honestly, that's not so bad seeing how it weighs 85 pounds in two-cylinder form and the result is the ultralight and lightweight sport aircraft guys really like these engines. The interesting thing is that everyone installing these has a short, individual, non-scavenging exhaust and their own ideas of what a proper intake should be. (usually a single carb hanging down low or some guys try the dual bike carb on each bank. Basically, they're not running optimized in any way aside from mixtures making them run right in the face of their shortcomings. Optimizing this shouldn't be difficult given the right valve sizes and work and cam selection as well as intake runner and exhaust lengths. The dyno charts from the testing of the VW engines for aviation over thirty years now have power falling off after 3400rpm and torque peak at 3k. that's fine as that customer base swings appropriately sized props; however, my potential application needs 4000 to 4300 rpm so it's a specific range that can be targeted. In this case, it involves shifting the torque peak nearly a thousand rpm up and making it fat as possible. The displacement listed is the maximum without seeing cylinder cracking or other stress issues. The balance is quite good as the pistons are not on the same journal, so they literally are boxing each other coming in and out together and the crank is counter balanced for that motion. (Case pressure is taken care of with pressure check valves.)

So, how would you address the opposed twin scenario of say, a BMW bike or something like this where the exhaust pulses are balanced. Can a 2-1 scavenge at that point? How would you go after this optimization idea?

Here is a video of a guy operating one of these engines outside of its power range at 4,000 rpm...once he levels out. Looks like a fun contraption he has.

Drakkon- Most Glorious and Upright Person of Genius

> Grindintosecond

Drakkon- Most Glorious and Upright Person of Genius

> Grindintosecond

03/29/2015 at 15:09 |

|

That is awesome. Supremely cool.

Exhaust pulse tuning seems unlikely given you only have two cylinders and the exhaust runners are fairly long. In order for pulse tuning to work, you need 1-2-3-4 with equal length exhaust tubes so you get an equal 1-2-3-4 racing down the pipes with equal gaps in between. Those gaps create very small vacuum pressures. Each of those little vacuums helps suck the exhaust charge out of the cylinder valve that just opened. I think your 1-2-1-2 isn't likely to help. Shorty exhaust are probably your best bet.

Intake probably has some advantages. I can't shed too much light on it without some more depth, but just parking the carb on a shorty intake is likely not getting you what you want. A longer intake, one particularly that is aimed in the same curvature of the port will give the engine the biggest gulp. 4,000 is relatively fast but the charge isn't moving so fast.

Chances are, they are using the shortest possible intake becasue they are the lightest weight. In your application, that's a big deal. Here is a relatively long dual-carb setup

And this.

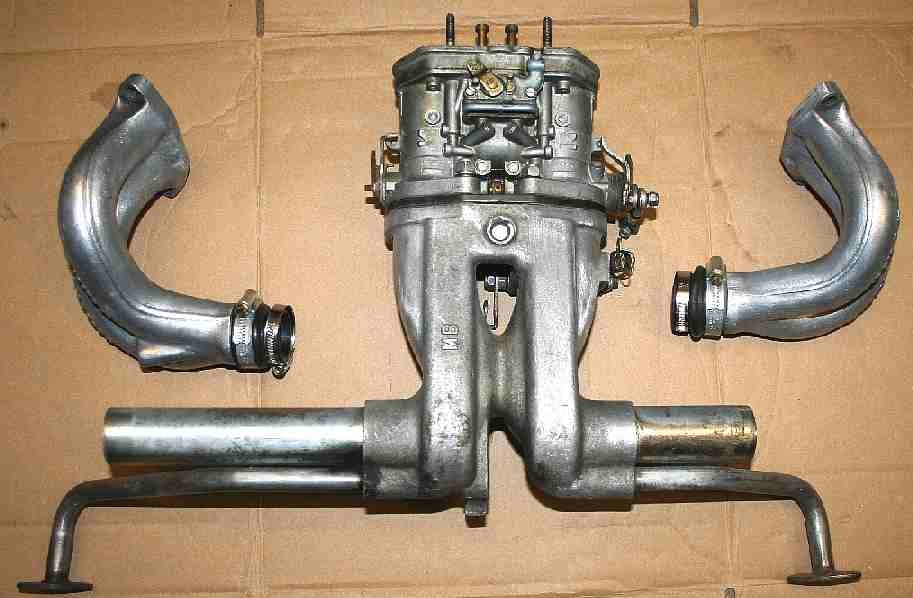

Or a very long center/single carb setup.

This looks really heavy. Very long, could be tuned to the right RPM that you like, but I would only see this working in a composite with fuel injection. Fiberglass would not appreciate gas vapor racing past all the time.

Grindintosecond

> Drakkon- Most Glorious and Upright Person of Genius

Grindintosecond

> Drakkon- Most Glorious and Upright Person of Genius

03/29/2015 at 16:12 |

|

Weight isn't too big of an issue in this regard. Here is the intake look on the full size 4 cylinder 2180 aerovee,

You can see the top intake runners here that originate from the underside, similar to the location in the first picture i posted showing the backside of the two-cylinder and the intake piping there. The underside carb location is more convenient from a fuel supply and air source standpoint. Given the actual runner length need, the carb can be located behind the back and not so low if it has to be a shorter runner. Now, the exhaust, I'm feeling you are right. I understand that there isn't enough mass flow to effectively scavenge in a merged system, but I went and searched something about the BMW motorcycle opposed twin and they use the individual exhaust per cylinder and use the length to scavenge that way. Just run a pipe long enough to get I suppose two cycles of exhaust in it and a waveform developes...causing wave reflection right back to the cylinder head making a scavenging system. This is something to look at perhaps.